One Call

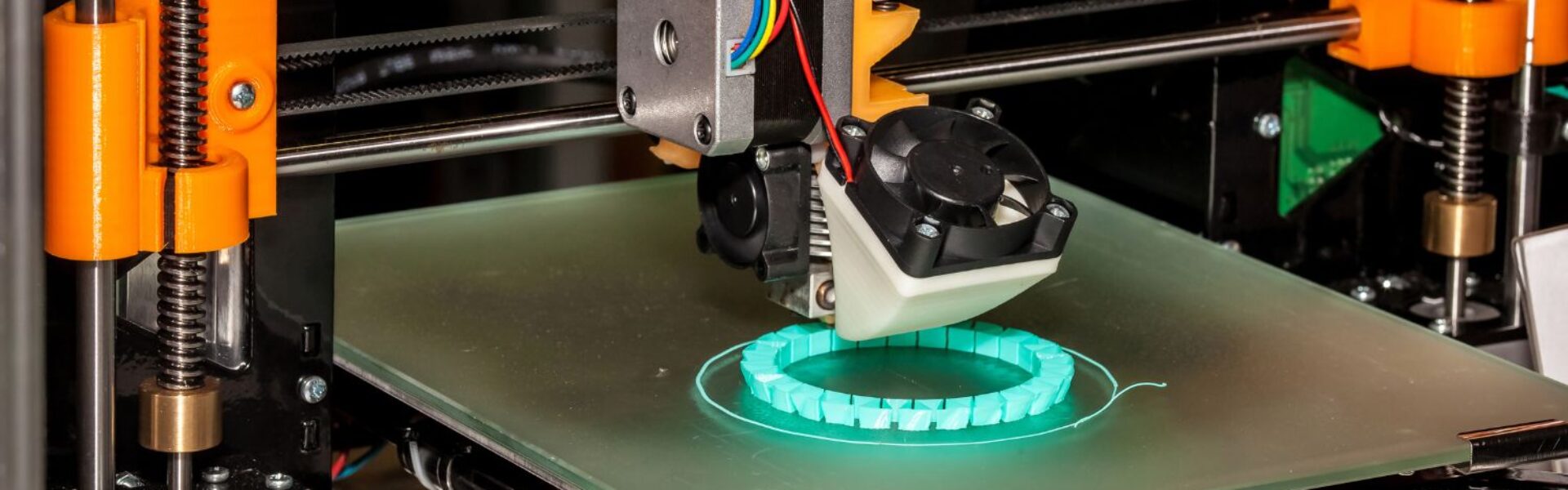

Additive Manufacturing, commonly known as 3D printing, is an innovative and transformative technology in the manufacturing industry. It involves creating three-dimensional objects layer by layer from digital models, allowing for the production of complex and customized structures that would be challenging or impossible to manufacture through traditional methods.

With being such a sophisticated vertical, challenges can arise that require elaborate solutions. That’s exactly what occurred for one of our additive manufacturing customers.

The client encountered a logistical hurdle when relocating a repair station from Albuquerque, NM, to Miami, FL. Recognizing the need for expertise, they turned to the seasoned professionals at ICAT Logistics.

Right Solution

The repair station, due to its over-dimensional size, mandated transportation via an air-ride enclosed trailer. Complicating matters, it had to reach its destination during the bustling period between Christmas and New Year’s Day—a time marked by heightened logistical challenges. The client insisted on a dedicated truck solely for their freight, manned by a team of TSA-certified drivers.

Despite the tight timeframe and stringent shipping prerequisites, ICAT Logistics took charge. The team vigilantly tracked the shipment’s progress, going above and beyond by working after hours when the initial truck faced mechanical issues. Collaborating closely with the drivers, they seamlessly reloaded the repair station onto a new truck, ensuring a safe and timely journey.

Done!

From initiation to completion, the ICAT team demonstrated unwavering commitment to delivering the repair station on schedule. Their real-time updates and adept problem-solving not only exceeded the client’s expectations but also solidified ICAT Logistics as the preferred choice for all future shipments.

Study Details

- Industry Industrial

- Capabilities Domestic Freight Ground Freight Unique Cargo & Projects